NRC Ratings & Operable Partitions

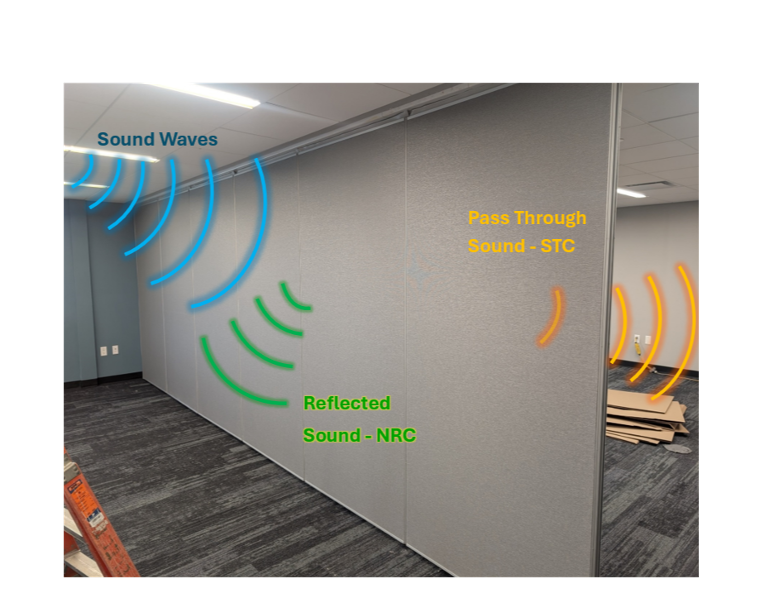

Acoustic performance within a space typically involves two primary concerns:

While architectural changes can reduce these issues, an effective acoustic solution is the use of sound-absorptive materials that limit reverberation time (the duration sound persists after the source stops) and control reflections. This is where the Noise Reduction Coefficient (NRC) comes in.

NRC of 0.00 = No absorption (total reflection)

NRC of 1.00 = Total absorption (no reflection)

For example, a material with an NRC of 0.90 absorbs 90% of sound within the tested frequency range and reflects 10%.

Important Note: NRC ratings do not account for low (<250 Hz) or high-frequency (>2000 Hz) sounds—such as those from drums, HVAC equipment, or musical instruments like tubas or pianos.

- Noise build-up within the space

- Sound transmission between spaces

Understanding Noise Build-Up

Noise accumulation in a room is often caused by reverberation—echoes or sustained sound reflections that occur in large spaces with hard, reflective surfaces like brick, concrete, glass, gypsum, or tile. Additionally, focused reflections can result from curved architectural features such as domes, peaks, or concave surfaces.While architectural changes can reduce these issues, an effective acoustic solution is the use of sound-absorptive materials that limit reverberation time (the duration sound persists after the source stops) and control reflections. This is where the Noise Reduction Coefficient (NRC) comes in.

What Is NRC?

The Noise Reduction Coefficient (NRC) is a single-number rating that indicates how well a material absorbs sound within the mid-frequency range (250, 500, 1000, and 2000 Hz). It is determined using standardized ASTM testing procedures (ASTM C423) in reverberation rooms and reflects the average absorption performance.NRC of 0.00 = No absorption (total reflection)

NRC of 1.00 = Total absorption (no reflection)

For example, a material with an NRC of 0.90 absorbs 90% of sound within the tested frequency range and reflects 10%.

Important Note: NRC ratings do not account for low (<250 Hz) or high-frequency (>2000 Hz) sounds—such as those from drums, HVAC equipment, or musical instruments like tubas or pianos.

Application to Operable Partitions

The primary role of an operable partition is to divide space, visually and acoustically, by blocking sound transmission (measured by STC, or Sound Transmission Class). However, on occasion, specifications may require both STC and NRC ratings—sound isolation and absorption in a single system.- There are two ways to add NRC to partitions:

- 1. Perforated Panel Skins – Metal skins are perforated to allow sound to reach an absorptive core inside the panel. Provides NRC but significantly reduces STC.

- 2. Applied Acoustical Panels – Acoustical panels are attached to the panel face. Adds NRC while preserving STC but increases stacking depth.

Key Considerations

- Drilling holes in a high-STC panel for NRC can allow more sound (like drum noise) to pass through, reducing effectiveness.

- When operable partitions are used, the space is typically occupied by people—who are naturally sound-absorptive.

- It’s more effective to add absorption through walls, ceilings, or furnishings.

- NRC ratings are based on lab conditions; field results often differ.

- Read the fine print: NRC test results may be influenced by materials like fiberglass backing.